Zero-Touch field service management software for manufacturing services

Keep production lines running with Zero-Touch automation. Fieldcode FSM software schedules maintenance automatically, tracks assets in real time, and ensures fast service response—so efficiency and uptime are never compromised.

Get a demo

Why manufacturers choose Fieldcode

Minimize equipment downtime and prevent costly breakdowns

Automated preventive maintenance scheduling ensures machines receive timely servicing, reducing unplanned downtime and improving OEE (Overall Equipment Effectiveness).

Respond instantly to critical equipment failures

Enable real-time emergency dispatch when unexpected failures occur. Fieldcode ensures the nearest available technician is assigned immediately, reducing Mean Time to Repair (MTTR).

Eliminate repair delays caused by missing spare parts

Real-time spare parts and inventory tracking ensures replacement parts are available when needed. Automated restocking alerts help minimize supply chain disruptions and keep production on schedule.

Keep maintenance teams compliant with industry regulations

Digital service records, automated checklists, and compliance tracking ensure your teams follow ISO, OSHA, and industry-specific regulations—without manual paperwork.

Essential features for automated manufacturing maintenance

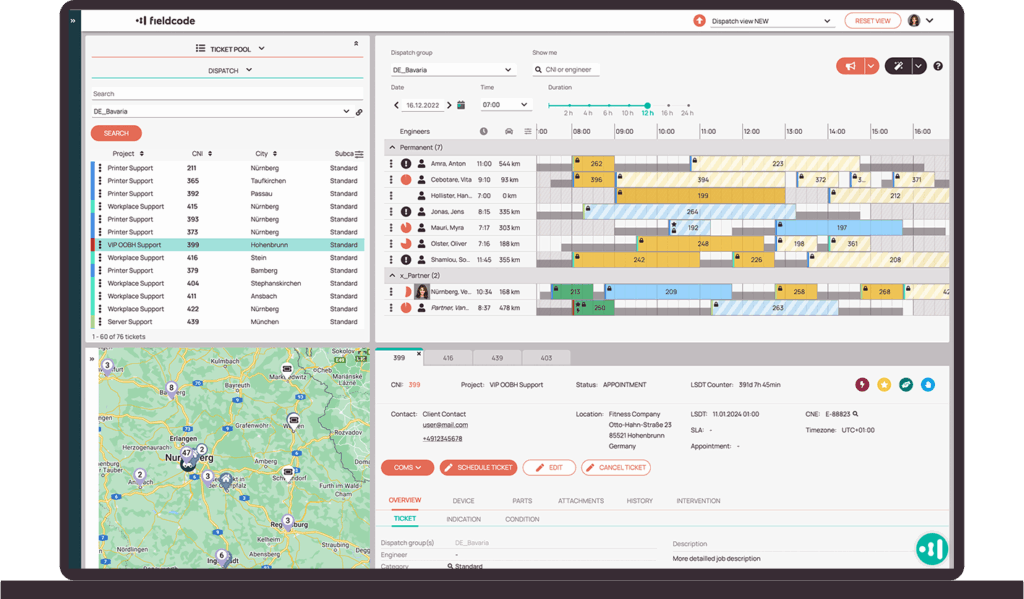

Smart work order management

Schedule, assign, and track maintenance jobs in real time—ensuring machines get serviced before they fail. Automated dispatching ensures the right technician is assigned based on skillset, location, and availability.

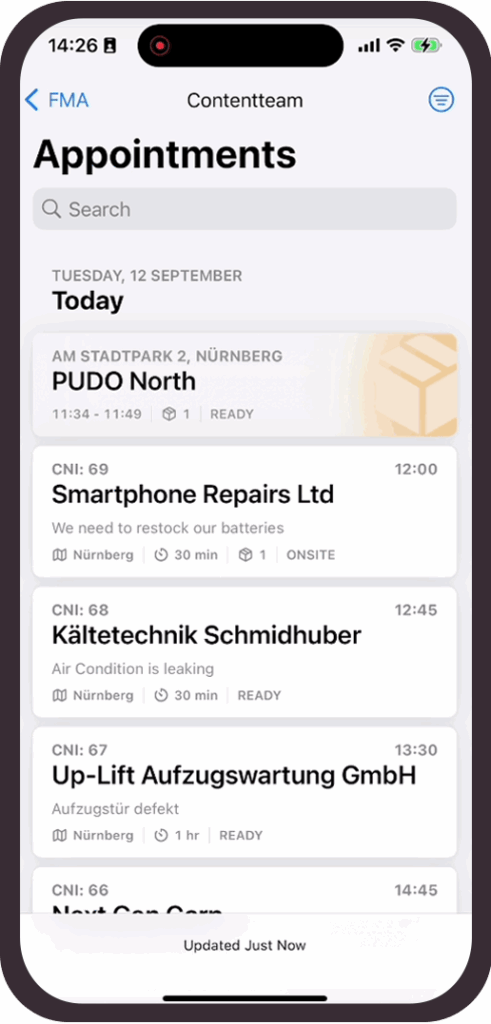

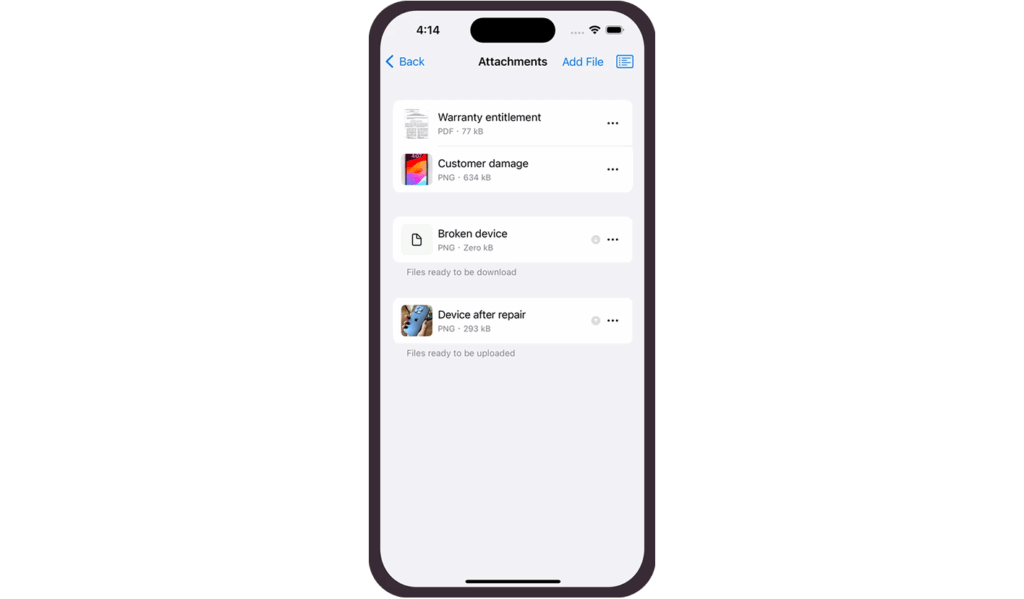

Mobile app with guided workflows

Equip service teams with instant job details, guided checklists, and offline capabilities. Workflows update automatically, so repairs stay on schedule—even in low-connectivity areas.

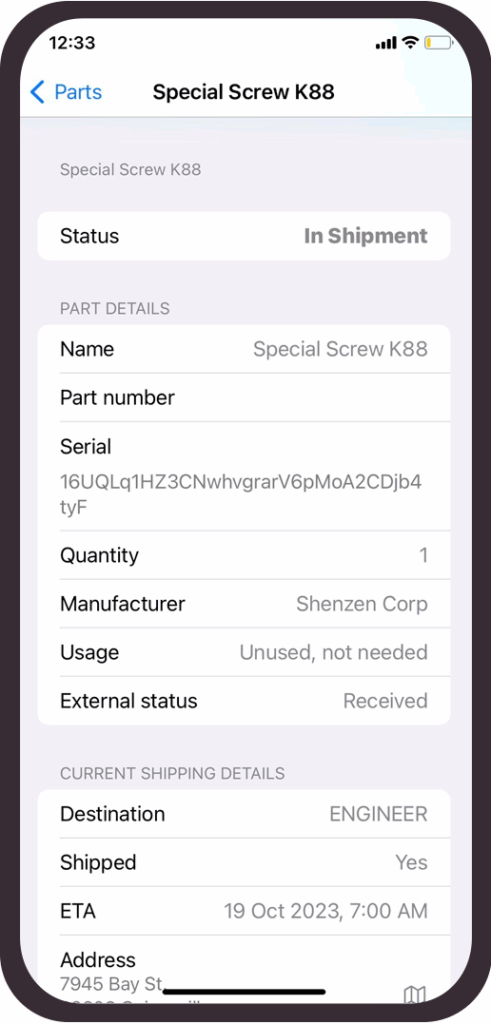

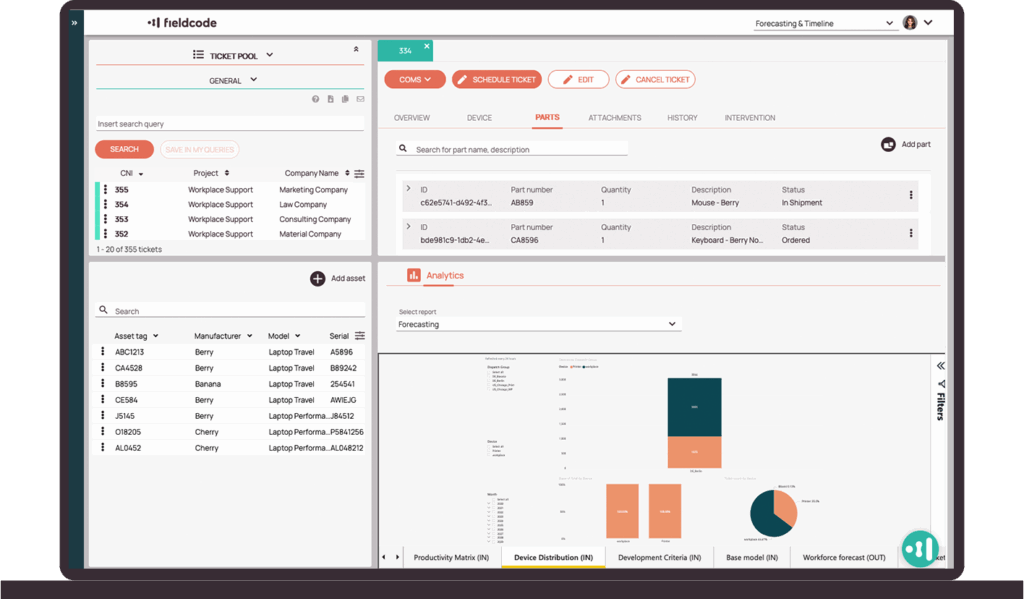

Real-time spare parts and inventory tracking

Keep track of critical spare parts, automate restocking alerts and ensure replacement parts are available before a breakdown occurs.

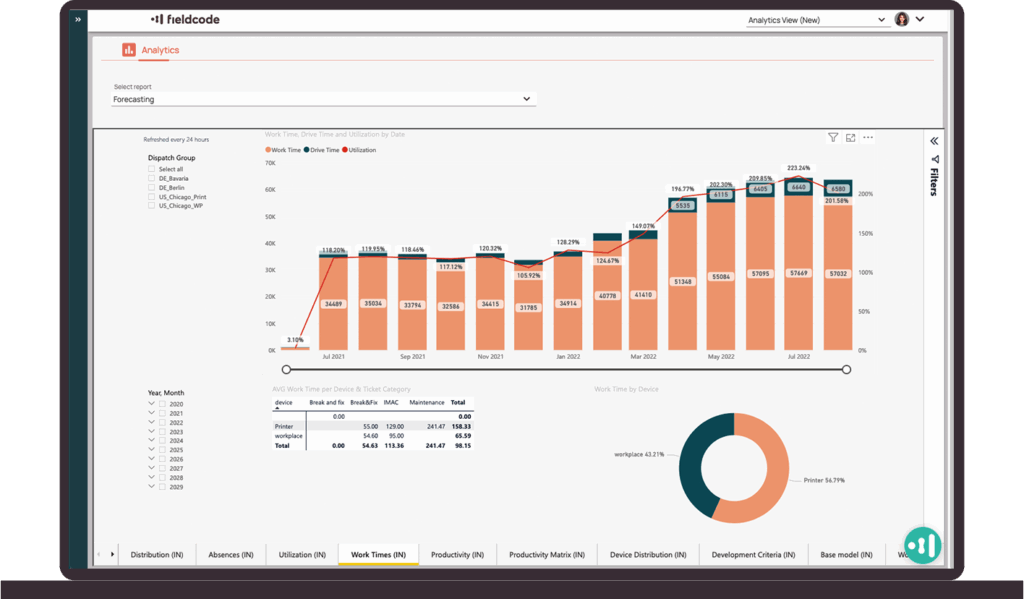

Centralized maintenance insights and reporting

Monitor work orders, technician performance, and repair costs in real time. Gain actionable insights to reduce maintenance costs and optimize service efficiency.

Key functions for automated maintenance in manufacturing

Planned & preventative maintenance

Automate maintenance scheduling to reduce downtime and extend asset lifespan.

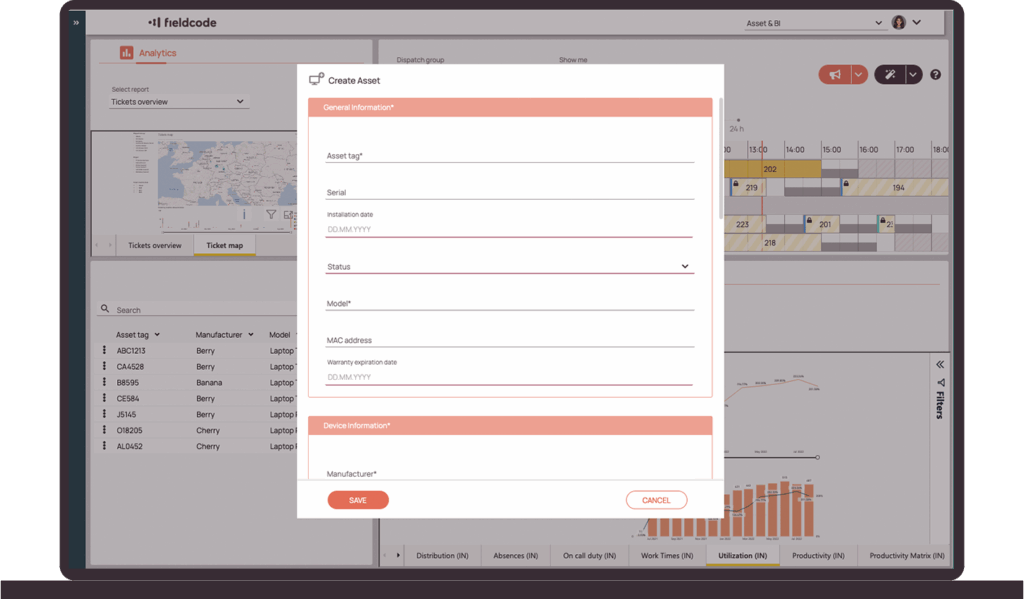

Asset & equipment management

Maintain detailed service records, manage warranties, and optimize maintenance schedules based on contracts or predefined schedules.

Compliance & audit-ready service records

Keep digital maintenance logs to simplify audits and ensure compliance with industry standards.Technicians can attach photos, service reports, and other documents directly to work orders—creating a complete, verifiable maintenance history.

reduction of maintenance costs

increased monthly revenue

increased productivity of field workers

FAQ

1. How does Fieldcode help reduce unplanned downtime?

Fieldcode automates preventive maintenance scheduling and ensures technicians receive real-time service alerts, reducing unexpected equipment failures and keeping production lines running.

2. How does Fieldcode improve spare parts availability?

Fieldcode offers real-time inventory tracking and automated restocking alerts, ensuring that critical spare parts are always available—preventing production delays caused by missing components.

3. Can Fieldcode support maintenance across multiple factory locations?

Yes. Fieldcode provides centralized job tracking and reporting across multiple facilities, allowing maintenance teams to coordinate seamlessly, standardize processes, and optimize resource allocation globally.

4. How does Fieldcode ensure compliance with manufacturing industry regulations?

Fieldcode digitally records all maintenance activities, provides automated checklists, compliance tracking, and audit-ready reports—ensuring adherence to ISO, OSHA, and industry-specific regulations while reducing paperwork.

5. How does Fieldcode optimize technician scheduling?

Our Zero-Touch automated scheduling assigns the best technician based on expertise, location, and urgency—cutting response times and improving first-time fix rates.

See how Fieldcode maximizes uptime and efficiency

Prevent machine failures and service delays before they disrupt production. Request a demo, and our experts will show you how Fieldcode optimizes maintenance, streamlines service coordination, and keeps your production lines moving.

Get a demo