Kapsch achieves Zero-Touch control in transport management with Fieldcode

Kapsch TrafficCom delivers critical transport infrastructure worldwide across 50+ countries. To maintain this scale, the company needed precise, coordinated field execution. With Fieldcode Zero-Touch FSM, Kapsch unified internal and external teams on one platform, gaining real-time visibility, standardized processes, and SLA oversight. Dispatch is faster, compliance trackable, and infrastructure uptime protected.

Get a demo

About Kapsch TrafficCom

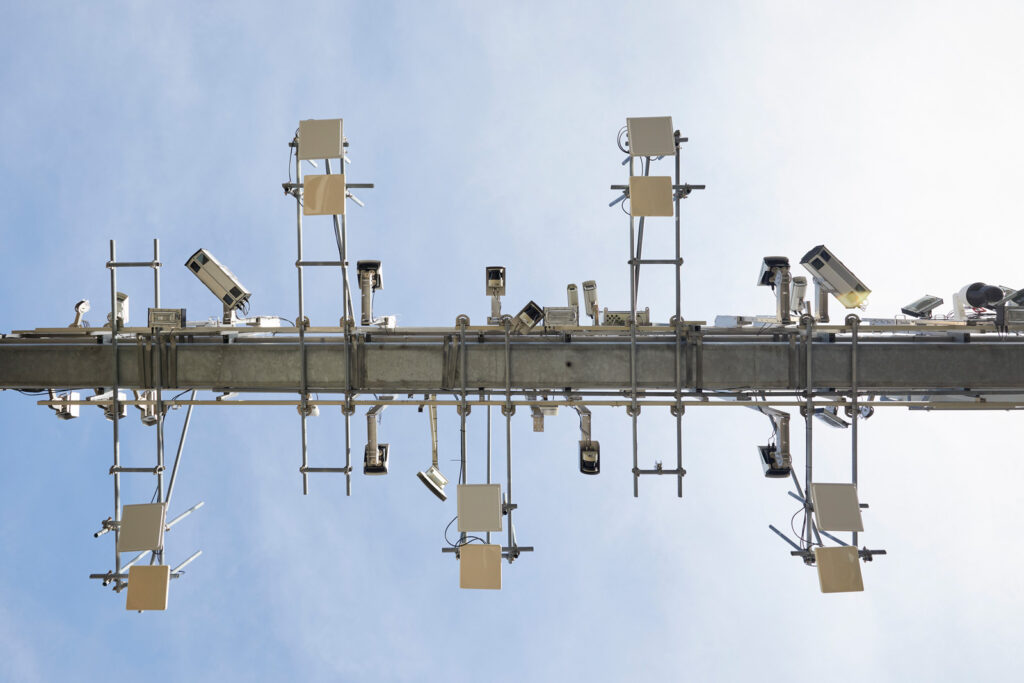

Kapsch builds and operates intelligent transport systems (ITS), including satellite tolling, SCADA, traffic signal optimization, and connected corridor infrastructure. Their solutions span highways, tunnels, urban mobility, and vehicle-to-everything (V2X) communications.

| Company | Kapsch TrafficCom |

| Industry | Mobility infrastructure and intelligent transport systems (ITS) |

| Size | ~6,700 employees |

| Headquarters | Vienna, Austria |

| Website | www.kapsch.net |

The challenge: Predictive alerts stuck in outdated workflows

Kapsch operates at the intersection of high-availability infrastructure and public-sector accountability. While their traffic and tolling platforms deliver predictive insights, the execution layer—technician dispatch, maintenance scheduling, subcontractor oversight—still depended on fragmented tools and manual workflows. Predictive alerts often stalled in operational bottlenecks, requiring human intervention before work could begin.

Key pain points included

Fragmented job coordination across internal teams, regional partners, and infrastructure agencies

Siloed data that slowed SLA reporting and masked risks in service delivery

Inconsistent workflows across subcontractors, leading to non-uniform compliance documentation

Reactive dispatching, disconnected from the predictive triggers surfaced by infrastructure monitoring systems

High administrative burden to manually track tasks, log completion, and reconcile service tickets

Lack of real-time visibility into technician activity or job status, risking downtime on high-priority assets

The result:

Friction between predictive intelligence and on-the-ground execution—where every minute of delay could impact enforcement, congestion, or system uptime.

The solution: Fieldcode Zero-Touch FSM as the execution layer for intelligent mobility

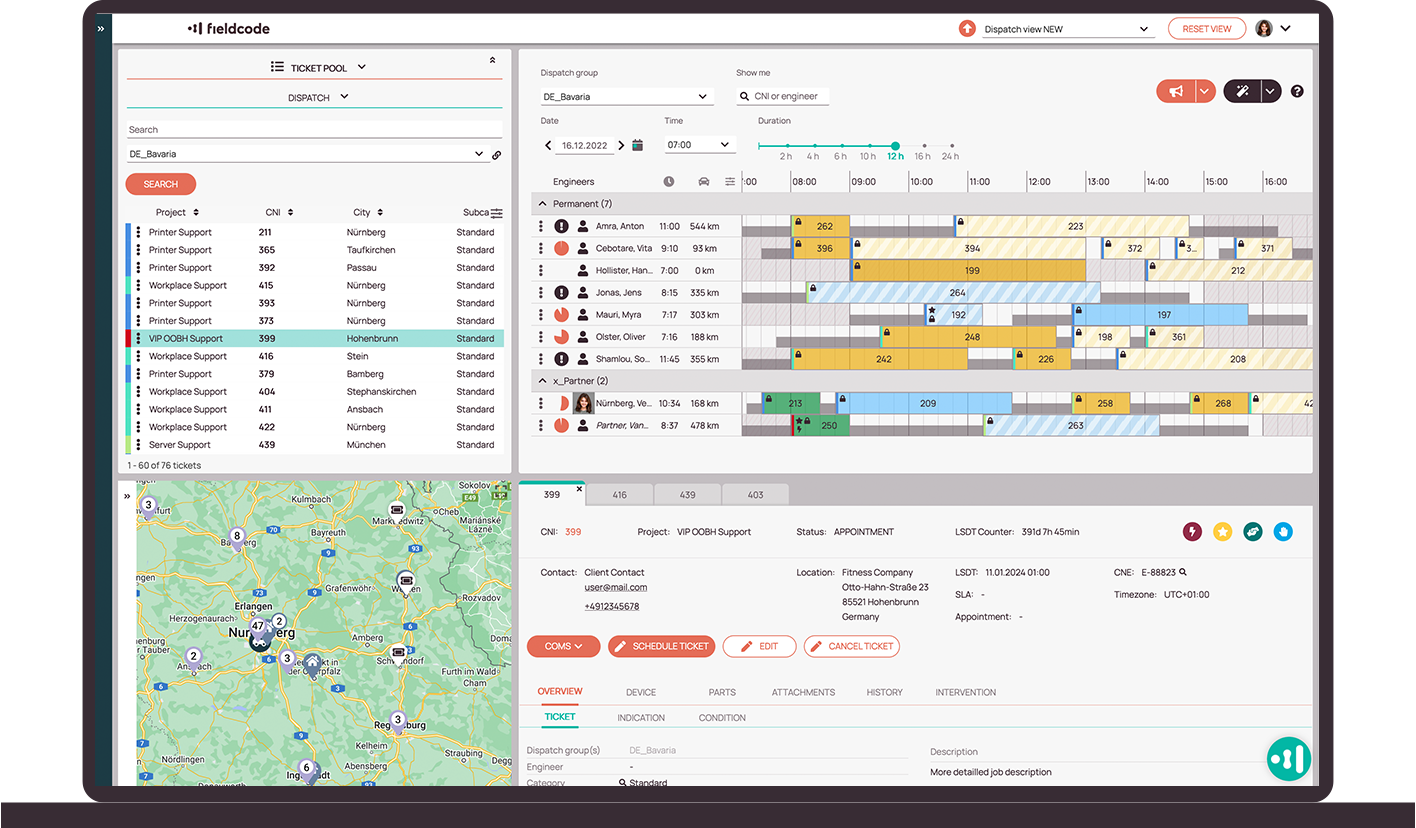

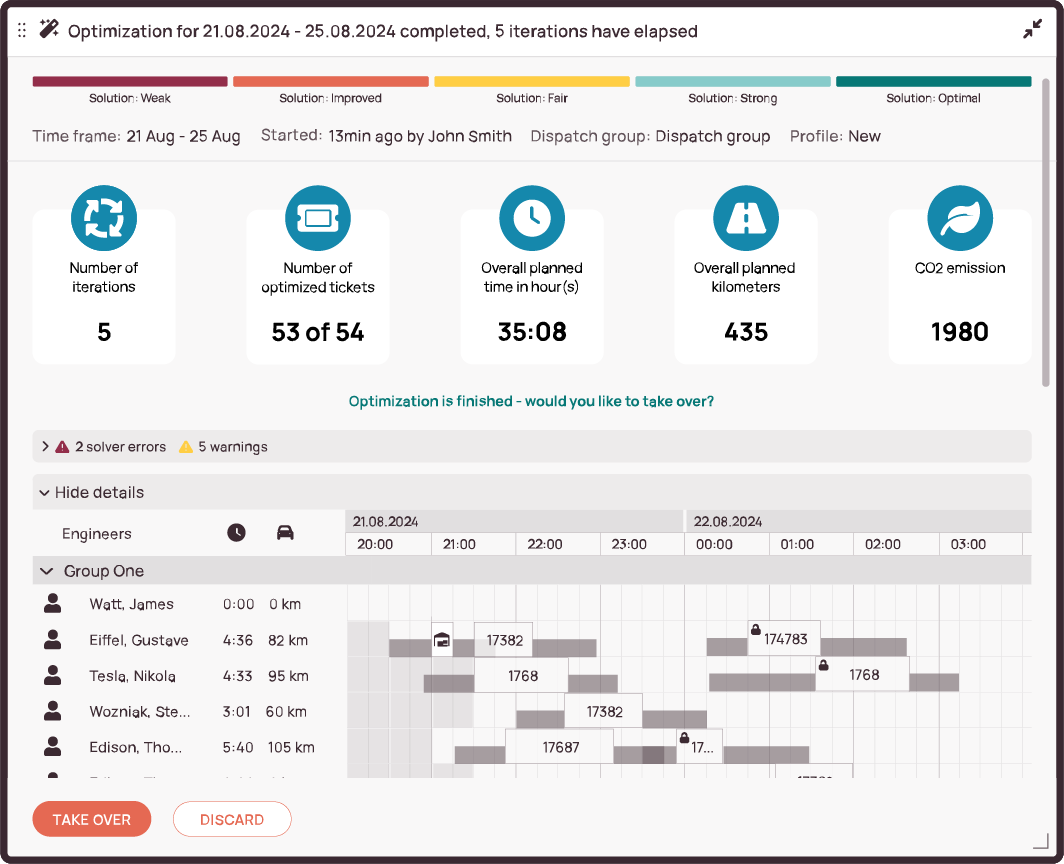

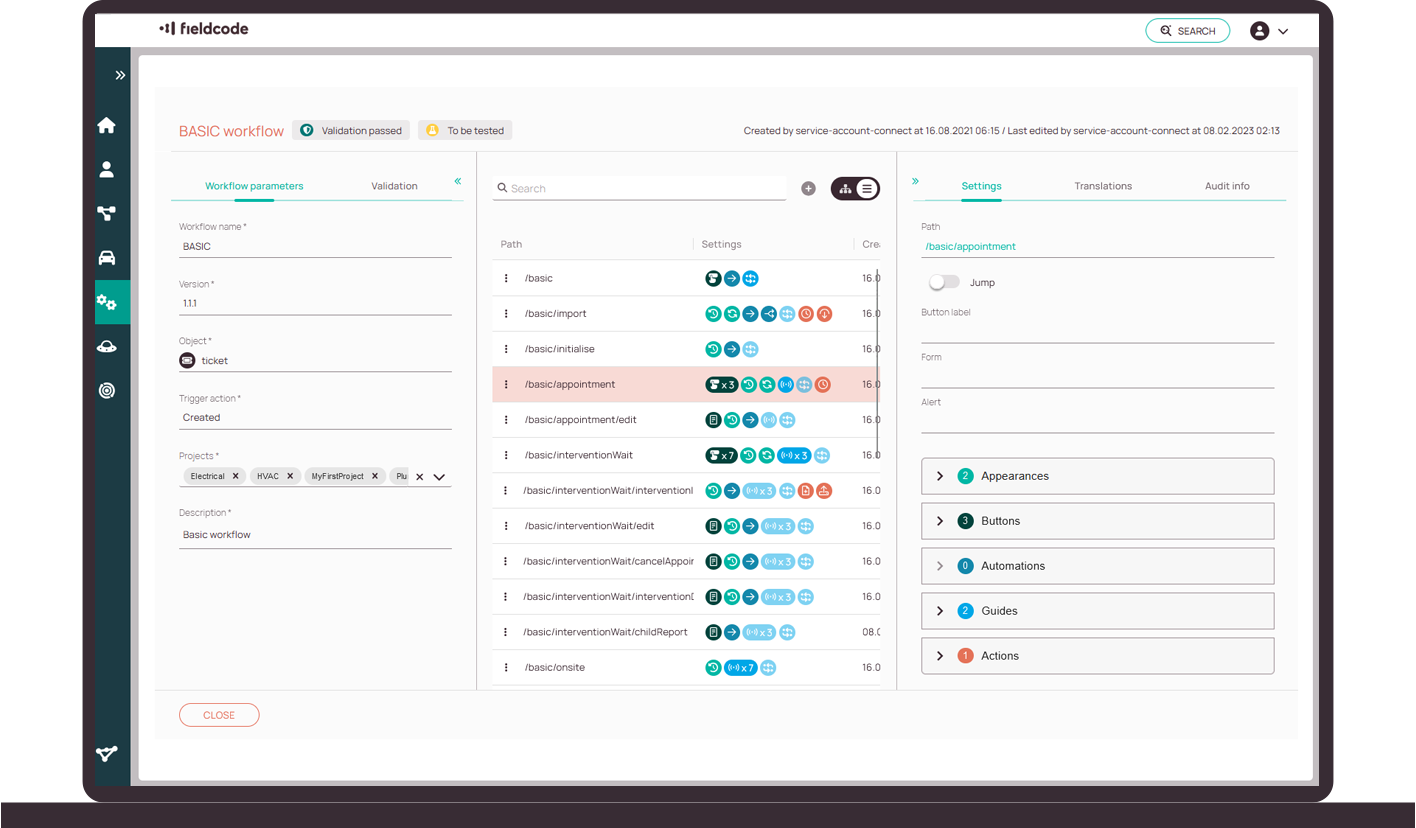

Fieldcode Zero-Touch FSM became Kapsch’s foundation for coordinating all field tasks—across continents, vendors, and asset types—without manual dispatch intervention. Predictive triggers from smart mobility control systems flow directly into automated scheduling, ensuring the right technician, with the right skills, is assigned before issues escalate. This end-to-end automation connects predictive system outputs with real-time job execution, enabling precise, SLA-compliant field operations at scale.

Key improvements

Global job visibility

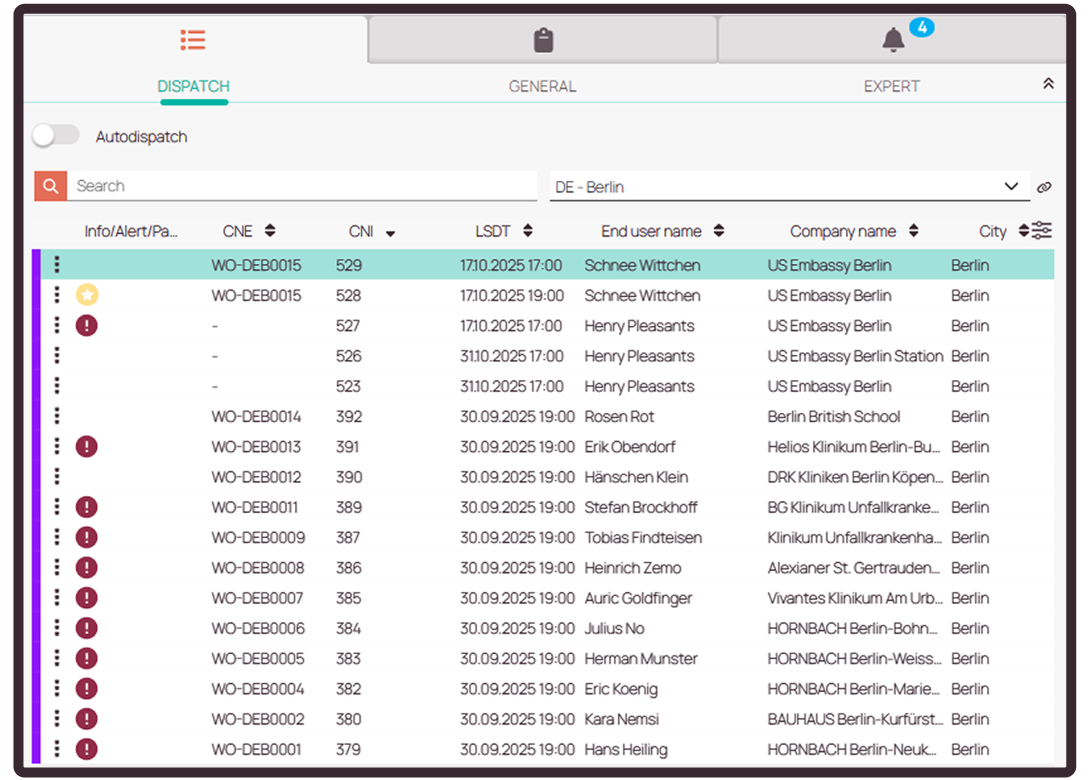

Real-time dashboards show job progress, technician status, and SLA countdowns across countries.

Intelligent, Zero-Touch dispatching

Jobs are automatically assigned based on location, technician certification (e.g., SCADA, tolling systems), availability, and urgency—without manual intervention.

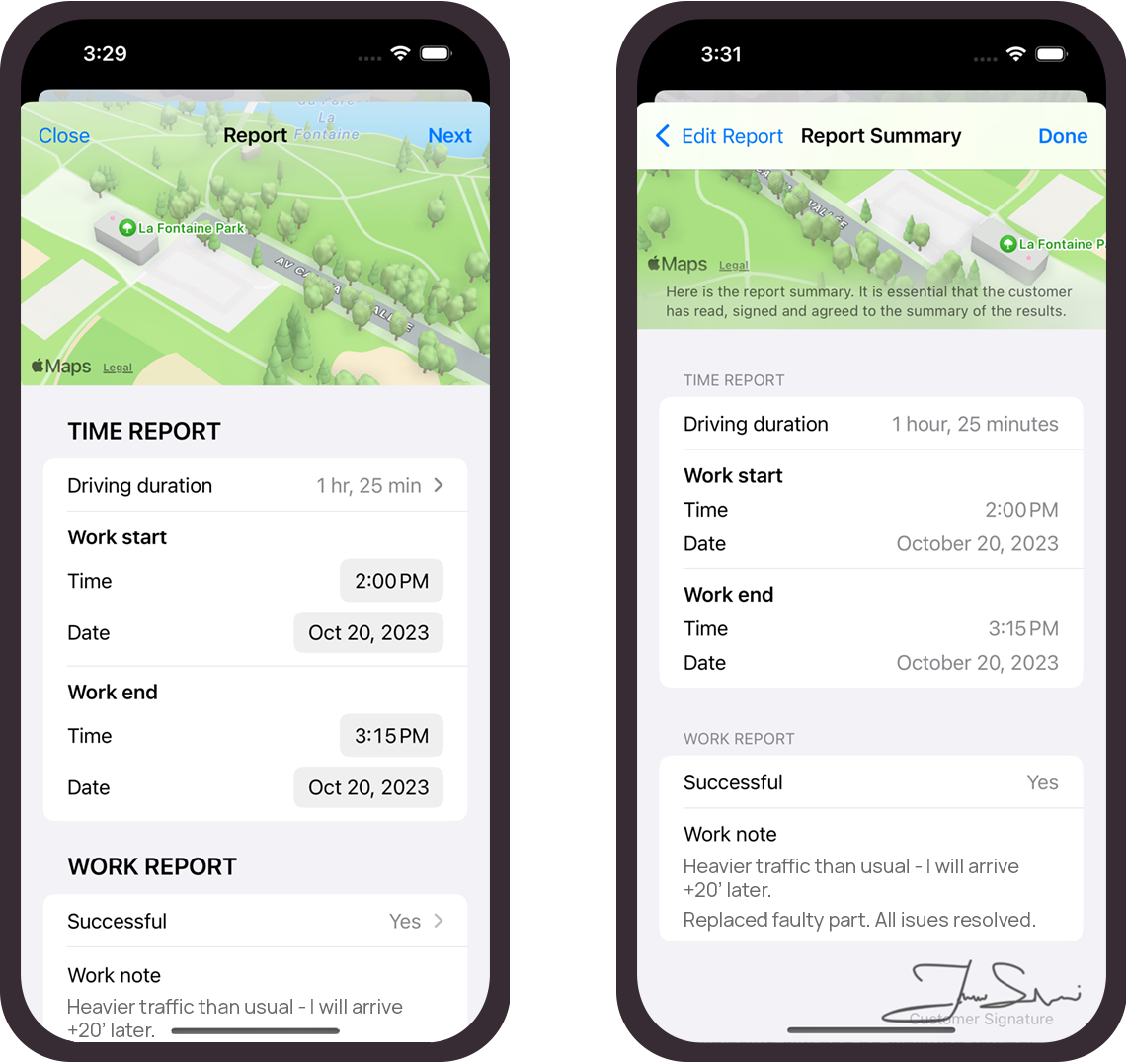

Field-ready mobile app

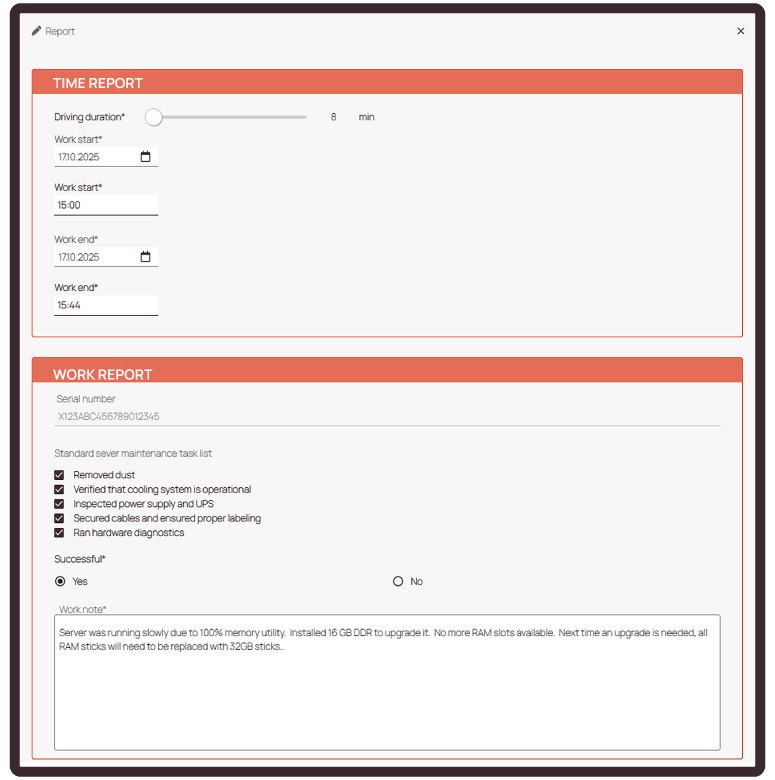

Technicians capture data on-site—photos, digital checklists, client signatures—even in offline environments.

Standardized workflows for partners

Subcontractors follow the same structured processes as internal teams, ensuring data consistency and auditability.

Live SLA alerts

Dispatchers are notified when jobs approach SLA thresholds, with visual dashboards tracking risk in real time.

Automated reporting & compliance logs

Ticket closures generate standardized reports, reducing admin time and simplifying contract proof.

Results from Kapsch’s Fieldcode deployment

By shifting to a Zero-Touch operating model, Kapsch reduced human coordination effort, accelerated response times, and turned predictive alerts into immediate field actions. These improvements support the company’s strategy to streamline global service delivery, minimize regional variability, and scale field operations without increasing administrative overhead.

We’ve built highly predictive mobility systems—but we needed execution to match that intelligence. With Fieldcode, we finally bridged the gap between what our systems know and what our teams do in the field.

Features that enabled Kapsch’s transformation

Geo-aware smart dispatch with skill tagging and workload balancing

Offline-ready mobile technician app with checklists, documentation, and digital sign-off

Customizable job types and workflows tailored to ITS infrastructure, including tolling, traffic signals, V2X and SCADA service tasks

Role-based access and partner permission control

SLA dashboards with proactive alerting and escalation workflows

Automated email/SMS milestone notifications for infrastructure agencies

Analytics dashboards tracking performance KPIs, open tickets, and uptime metrics

FAQ

1. Why does operational visibility matter in intelligent transport systems?

Tolling gantries, traffic signals, and connected roadside units don’t just need to be installed—they need to be inspected, updated, and maintained under strict SLAs. Any gap in execution puts safety, revenue, and reputation at risk. Fieldcode closes those gaps by:

- Scaling field operations in line with global infrastructure deployments

- Centralizing dispatch, job tracking, and technician coordination

- Standardizing service execution across internal and subcontracted teams

- Providing real-time SLA monitoring and early warning alerts

- Reducing manual admin to accelerate close-out and compliance

2. How does Fieldcode enable Zero-Touch field execution?

By linking predictive alerts from systems i.e. like EcoTrafiX directly to automated dispatch workflows, Fieldcode removes the need for manual scheduling. This ensures technicians are deployed proactively, without human delays.

3. Can Fieldcode manage subcontractor performance across multiple countries?

Yes. Fieldcode enforces the same workflows, checklists, and SLA rules for subcontractors as for internal teams. Performance data is tracked in real time, so vendors in different regions operate with the same standards and their results can be compared side-by-side.

4. How does Fieldcode reduce administrative workload in large-scale operations?

Technicians close jobs digitally from the field, including photos, signatures, and compliance forms. This data flows instantly into dashboards and reports, removing the need for manual entry, separate spreadsheets, or follow-up calls to confirm status.

Personalized Demo

Discover how to optimize your field service operations with a personalized demo tailored to your needs.

Get a demo