Smarter parts pickup and return scheduling for field teams

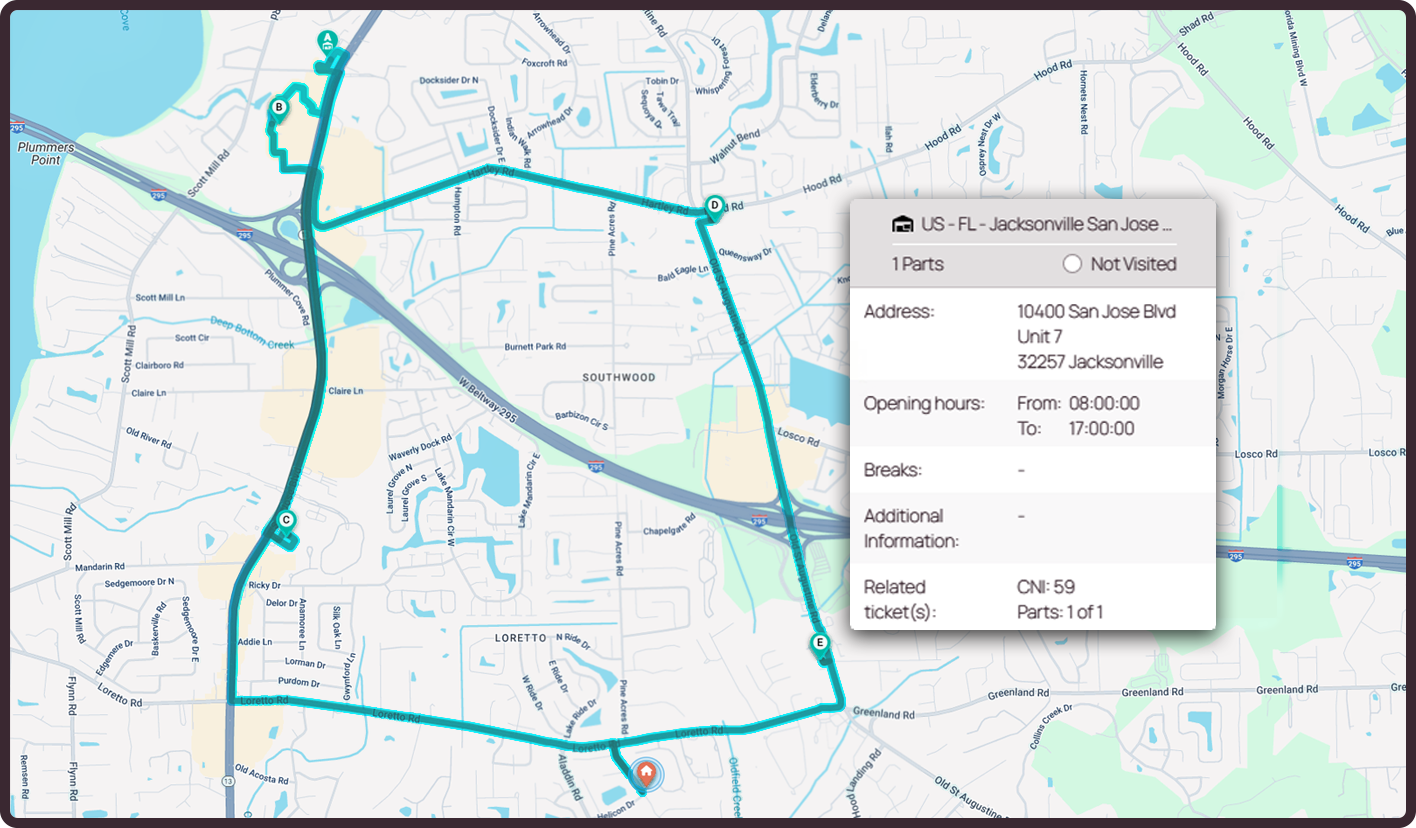

Optimize routes by automating scheduled pickups, returns, and access to stocked parts. Fieldcode’s FSM software turns parts logistics into an integrated aspect of daily operations – scheduling part pick-up/drop-off (PUDO) and forward stocking location (FSL) stops like jobs, with real-time parts tracking and full visibility before, during, and after the work.

Get a demo

Why service teams trust Fieldcode for parts handovers

Keep SLAs on track with reliable parts access. Most FSM tools treat pickups and returns as backend logistics. Fieldcode plans them like jobs – routed, timed, and optimized. Whether you’re using static FSL sites or a transactional PUDO network, the software factors in opening hours, technician location, SLA targets, and part availability without added planning.

PUDO stops and FSL pickups are embedded directly in the daily route

Access times and site rules are factored into scheduling

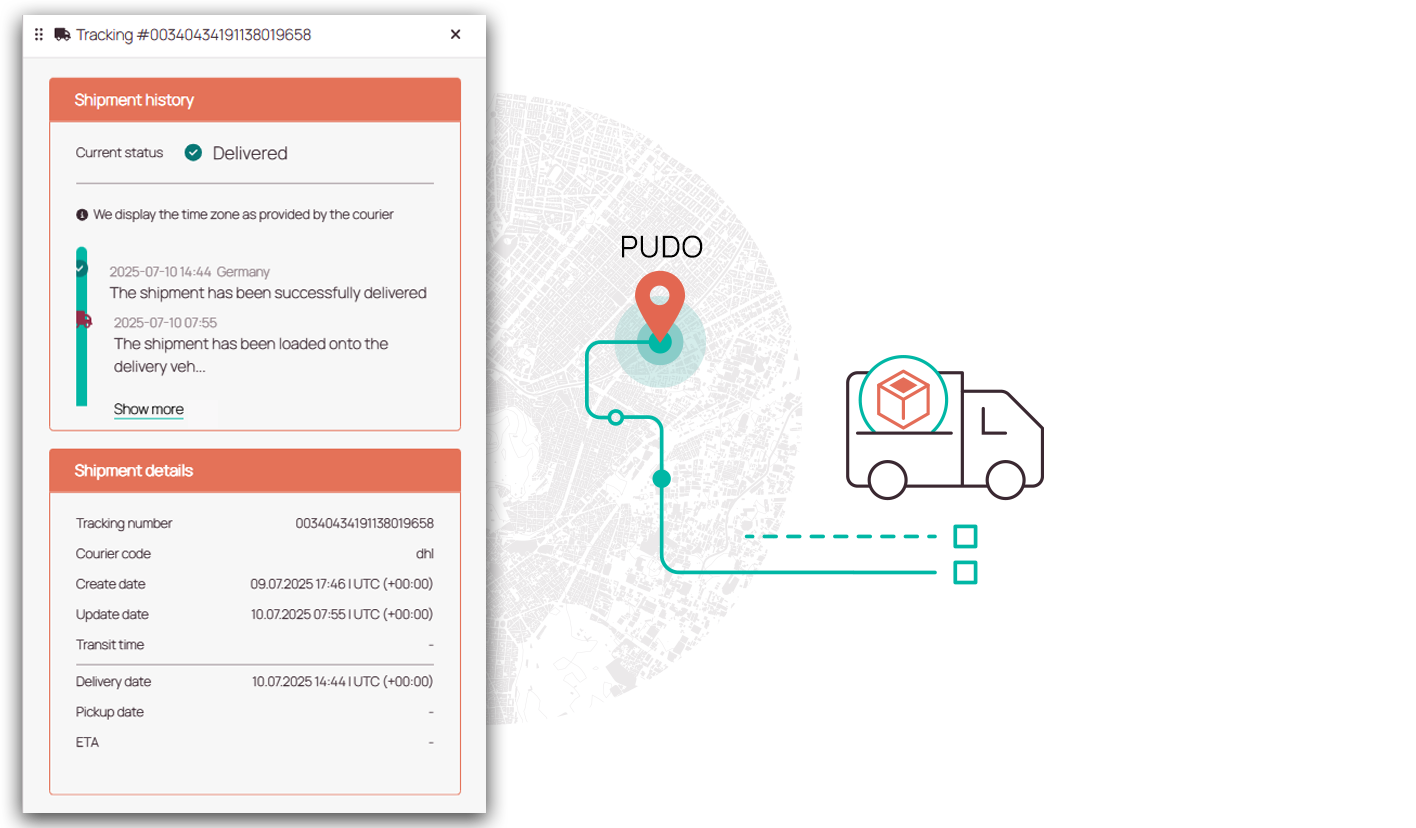

Parts tracking updates in real-time as jobs progress

Missed pickups are automatically rerouted to fallback sites

Integrated parts logistics for field service teams

Fieldcode connects directly to both in-house and third-party-operated parts locations, so it doesn’t matter who runs your PUDO or FSL points.

Works with internal and external PUDO/FSL operators

Out-of-the-box integrations for all major logistics providers like UPS, FedEx, and DHL

Live updates and routing even across mixed logistics networks

No custom API work or coordination overhead

Why Fieldcode leads in PUDO and parts routing

| Fieldcode | Most FSM Tools |

|---|---|

| PUDO/FSL stops automatically scheduled and routed | Parts logistics handled separately |

| Supports fallback routing | No route-aware backup logic |

| Real-time parts tracking | Often relies on manual updates |

| Live technician app updates | Requires manual coordination |

| Built-in—no ERP/WMS needed | Dependent on external systems |

| Built-in support for any PUDO/FSL operator | Requires custom API or manual sync |

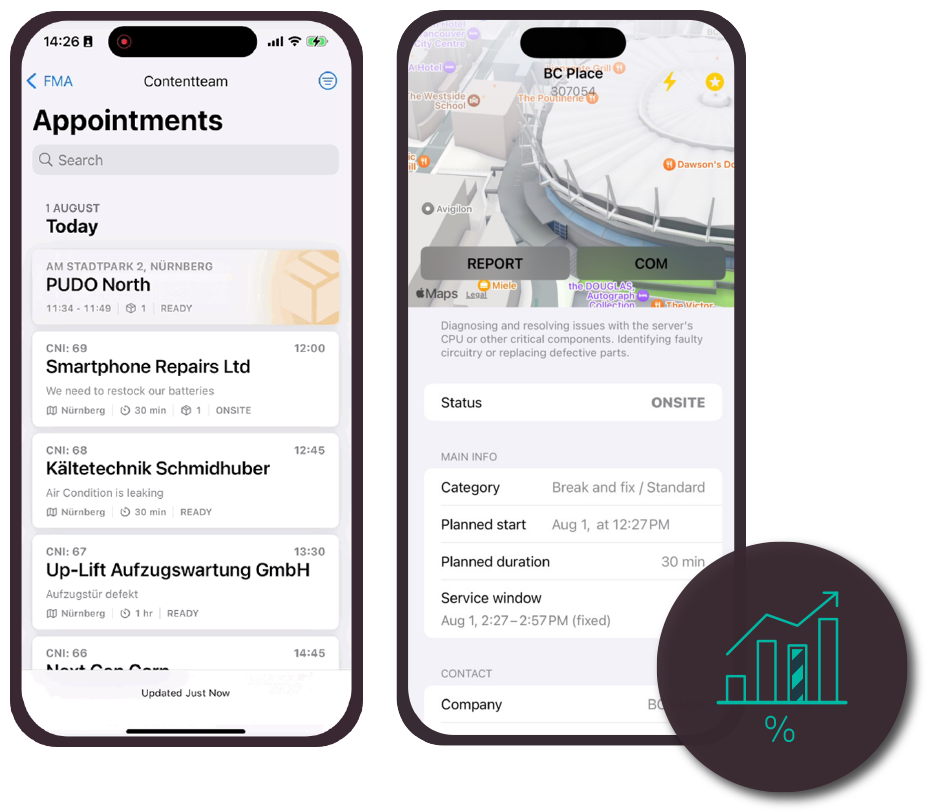

Measurable field service efficiency with Fieldcode

By planning PUDO and FSL stops as part of the route, Fieldcode helps teams:

- Cut drive time by eliminating detours

- Improve first-time fix rates with timely part availability

- Meet SLAs more reliably with proactive routing

- Track parts in real time – know what’s in motion, what’s pending, what’s delivered

- Free dispatchers from manual coordination

- Boost job capacity with fewer material delays

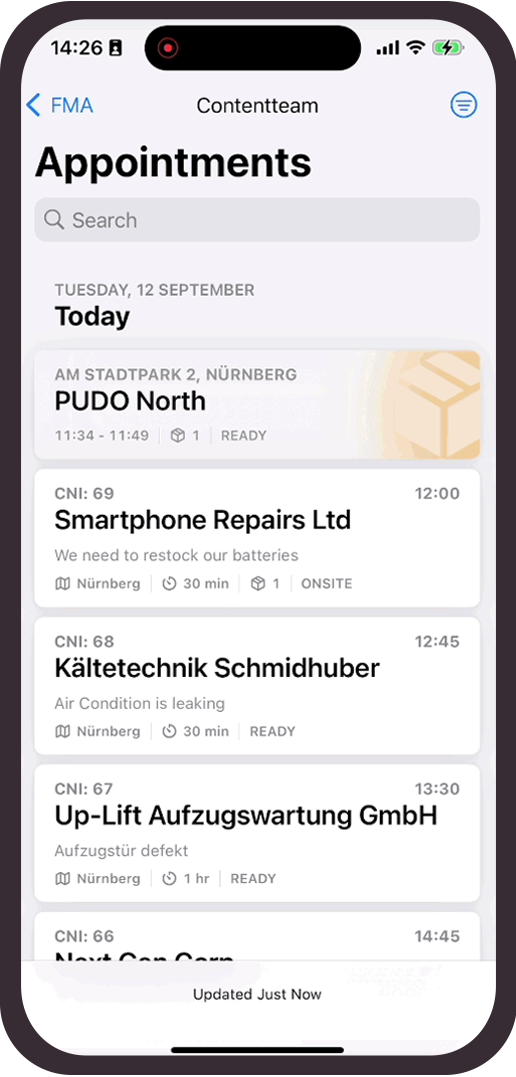

Every scheduled stop, pickup, return, or fallback is pushed to the mobile app in real time.

Faster repairs, less downtime

Technicians can pick up parts on the way to job sites or between appointments – no detours, no delays. That means faster fixes, reduced equipment downtime, and more time-on-tool where it counts

Get a demoFrequently asked questions

1. What is PUDO in field service, and how does it work with routing?

PUDO (Pick-Up/Drop-Off) refers to designated locations – like lockers or depots – where technicians collect or return service parts. Fieldcode integrates these stops into the route as scheduled appointments, optimizing timing based on job order, location, and availability.

2. How is an FSL different from a PUDO, and does Fieldcode support both?

FSLs (Field or Forward Stocking Locations) are fixed storage sites where parts are stored closer to service regions for planned access. In contrast, PUDO (Pick-Up/Drop-Off) locations are more transactional – used for quick scheduled pickups or returns. Fieldcode supports both, optimizing technician routes around them automatically.

3. Does Fieldcode account for location-specific access rules?

Yes. You can define opening hours, access restrictions, and public holidays for each PUDO or FSL location. The scheduling engine adjusts routes accordingly.

4. What happens if a pickup or return is missed?

Fallback locations are automatically triggered. Fieldcode automatically re-routes technicians to the next best option, minimizing downtime or delays.

5. How do technicians or drivers get their PUDO or FSL stops and parts info?

All stop updates, including pickups, drop-offs, fallback locations, and inventory changes, are sent directly to the technician’s mobile app – ensuring the latest route and part status are always visible.

Optimize parts flow across your field teams

Most FSM platforms bolt on parts logistics. Fieldcode makes it native. Whether you’re managing a depot network or trying to get a single part to the right place on time, Fieldcode takes the guesswork out of pickups and returns. Book a personalized demo and see how parts logistics should actually work.

Get a demo